We concentrate on graphite equipment-based process engineering and chemical environmental protection process engineering that is advantageous to energy conservation and emission reduction with other equipment. We combine and customize our process solution by using our expertise in material, equipment and process.

HCl Syntheses

- Customize plant capacity according to customer’s technical requirements

Production of hydrochloric acid with 1 ppm free chlorine

Production of HCl gas with lowest H2O content according to customer requirements

Reliable operation

Highest payback thanks to heat recovery system (e.g. steam recovery)Our References 30t/d 100% HCl (g) +320t/d Hydrochloric acid

30t/d 100% HCl (g) +320t/d Hydrochloric acid

Fujian, China 100t/d 100% HCl (g)

100t/d 100% HCl (g)

Neimenggu, China 125t/d HCl (g)

125t/d HCl (g)

Yunnan,China

Concentration of H2SO4

- Can design high concentration from 70 % to 96%

And low concentration from 25 % to 68 %

Natural or forced circulation

Two or three-stage concentration system at different pressure levels significantly reduce steam consumptionOur References Waste sulfuric acid regeneration in TiO2 industry

Waste sulfuric acid regeneration in TiO2 industry

Sichuan, China

5 t/h treated volume, H2SO4: 24%-69% Waste sulfuric acid concentration in TiO2 industry

Waste sulfuric acid concentration in TiO2 industry

Anhui, China

15t/h water evaporation, H2SO4: 20%~25% - 55%

Production of HCl gas from hydrochloric acid

- Customize plant capacity according to customer’s technical requirements

Conventional process/advanced process

Feed concentrations in the range of 25% to 35% HCl

Optimal design with least steam and cooling water consumptionOur References Conventional desorption 1t/h 31% hydrochloric acid

Conventional desorption 1t/h 31% hydrochloric acid

Hebei, China

Purification of HCl

- Customize plant capacity according to customer’s technical requirements

HCl gas is produced by distillation of hydrochloric acid solutione

Stripping columns with intensive fluid contact

Production of highly pure, dry HCl gas with low inert gas and moisture contents

Gas pressure and temperature in accordance with customer’s requirements

Minimized consumption of steam and cooling water by optimal design

No risk of explosion

Applications

sulfur method to produce refined chloroacetic acid with byproduct hydrochloric acid

Evaporation and crystallization

- If the solubility of the salt changes only a little at fluctuating temperatures the evaporation crystallization preferably find applications

In this process a solution is crystallized by evaporating the solvent through the supply of heat.

The special design of the evaporation chamber makes is possible to operate the evaporation crystallizer as classifying crystallizer.

In this case the crystals are separated by classification according to size in a sedimentation zone. The coarse portion may be discharged through an extra outlet while the fine portion remains in suspension.Our References Evaporation and crystallization MgSO4 pilot-plant

Evaporation and crystallization MgSO4 pilot-plant

0.3t/h water evaporation

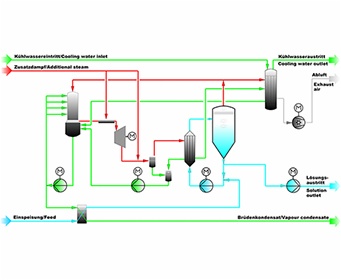

Mechanical vapor recompression

- If the cost of electric power are lower than the cost for the production of steam, it is advisable to operate the vapor compression by means of electric power

Live steam is only needed for starting-up of the plant

Besides single-stage radial compressors also multi-stage machines and axial compressors may find application

Electricity consumption of below 40Kwh per ton water evaporation

Low operation cost and high condensate quality

Mechanical vapor recompression may also be applied in multi-stage evaporation plants and evaporation crystallization plants.Applications

-evaporation of brine solutions in chlor-alkaline industry

-concentration of brine solutions in salt industry

-evaporation of aqueous solutions in chemical industry

-recycling of special metals

-concentration of waste water in environmental aspect

-evaporation of milk, whey, sugar solutions etc. in food and beverages industry

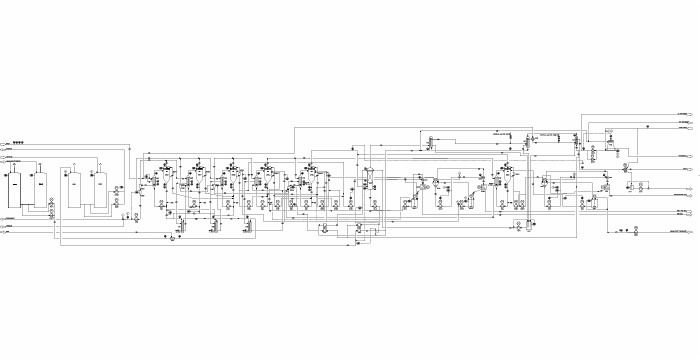

-concentration of solutions in petrochemical industryOur References Process flow diagram of MVR

Process flow diagram of MVR Titanium solution concentration with MVR to significantly reduce operating cost

Titanium solution concentration with MVR to significantly reduce operating cost

Capacity: 6.6t/h water evaporation

Brine osmosis in chlor-alkali industry

- Significantly extend the regeneration period of resin tower in brine treatment system

Decrease customer’s operation cost

Reduce the waste water effluent from the system

Cut down labor intensityOur References Shanghai chlor-alkali, China

Shanghai chlor-alkali, China

Shanghai, China Shanghai chlor-alkali, China

Shanghai chlor-alkali, China

Shanghai, China

Crystallization and recycling of NaCl/KCl in aluminum salt industry

- Multi-stage evaporation process can be used

Customize process solutions according to customer’s technical requirements

Lab test can be conducted before scaling up to the industrial phase

The lowest energy consumption achieved

Maximize the heat recovery in the system

Long service life